Commercial Air Duct Services VA

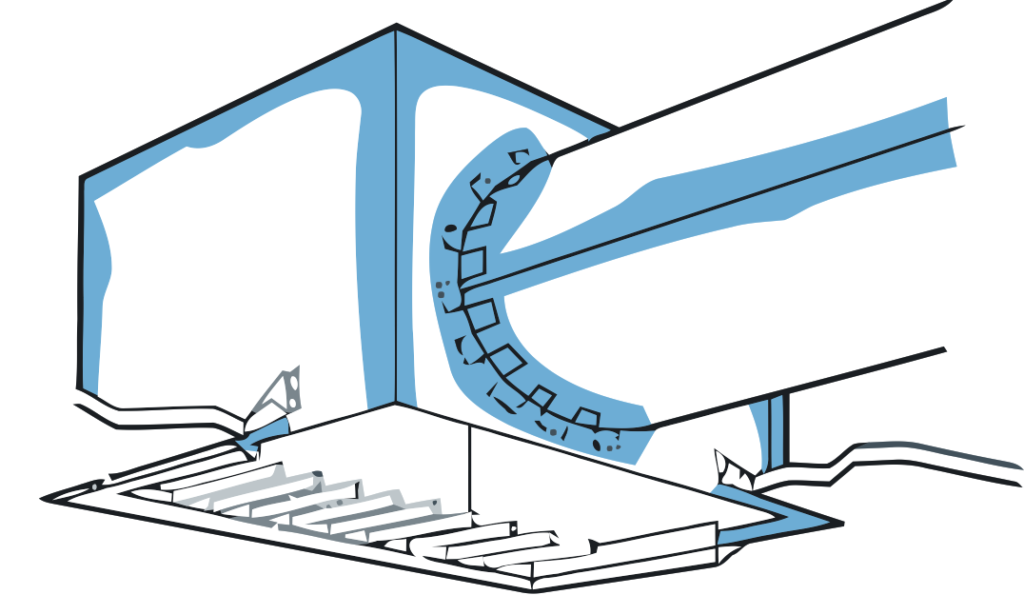

Air Duct Solutions utilizes Aeroseal technology to seal air duct leaks and saving clients up to 40 percent on their utility bills. This new technology allows Our qualified technicians will quickly identify, locate leaks and seal problem areas in air ducts that are troublesome- Providing building owners and facility managers a relatively inexpensive repair.

Our sealing process results in considerable energy savings, longer HVAC system life, increased thermal comfort, and improved indoor air quality.